The fascinating field of hover technology is essential to many developments in contemporary industry, science, and everyday consumer goods. Even though the term “vacuum” frequently conjures up the simple image of “no air”, the idea is far more complex and practical than that. Creating, managing, and utilising environments with pressures much lower than the typical atmospheric pressure around us is the focus of hoover technology. This makes it possible for engineers, scientists, and manufacturers to complete tasks that would be impossible under normal circumstances.

We must investigate how vacuums are made, how they are measured, and the range of applications they have across various industries in order to comprehend how vacuum technology functions and why it is significant. This guide will teach you the basics of hoover technology as well as its practical uses and how it will continue to influence our future in 2025 and beyond.

Vacuum technology: what is it?

The science and engineering techniques used to create and preserve low-pressure environments are referred to as vacuum technology. A vacuum is a reduced amount of air or gas relative to atmospheric pressure, not necessarily the total absence of air.

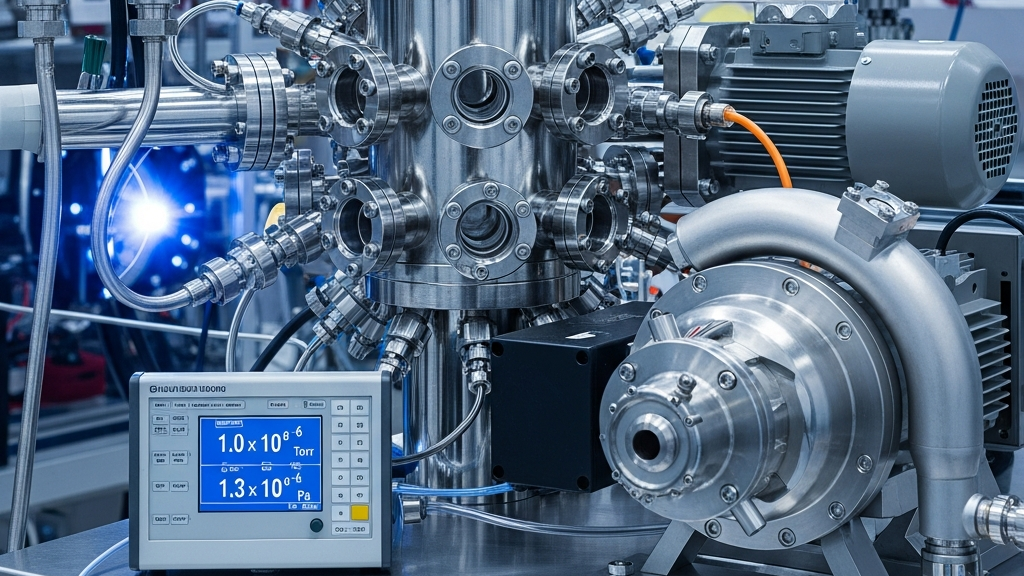

Units of measurement for pressure include millibars (mbar), Pascals (Pa), and Torr. The vacuum level increases as the pressure decreases. It is nearly impossible to create a perfect hoover, in which there are no particles. But thanks to modern technology, we can reach extremely low pressures where very few gas molecules are left.

The Operation of Vacuum Technology

Eliminating air and gas particles from a sealed chamber is the process of creating a vacuum. Various vacuum pump types, each intended for a particular vacuum level, are used to accomplish this. There are four primary steps in the basic process:

- Keeping things contained

It is necessary to create a sealed environment or chamber to keep outside air out. This chamber may be an industrial processing chamber, glass tube, or steel vessel. - Getting out

Pumps are used to remove air from the chamber. The majority of the atmospheric air is first removed by rotary pumps. Advanced pumps like diffusion, turbomolecular, or ion pumps carry on the process for deeper vacuums. - Quantification

To make sure the proper vacuum level is reached, sensors and gauges measure the pressure inside the chamber. - Command

By controlling temperature, outgassing, and leaks—all of which have the potential to release trapped gases from surfaces—the system keeps the vacuum level constant.

Because even the smallest leak or temperature change can affect vacuum quality, this entire process necessitates accuracy and ongoing monitoring.

Vacuum Level Types

There are various ranges into which hoover levels fall:

- Low Vacuum: A little lower than atmospheric pressure. utilised in packaging machines and home hoover cleaners.

- Food preservation and welding are two industrial processes that use a medium vacuum.

- High Vacuum: Necessary for scientific instruments like electron microscopes.

- Ultra-High and Extreme Vacuum: Used in semiconductor manufacturing, space simulation chambers, and particle accelerators.

Specialised pumps, seals, and monitoring systems are needed at each level.

Systems of Vacuum Technology Components

Several essential parts make up a typical hoover system:

- Air is extracted from the chamber by a vacuum pump.

- Pressure gauges: To guarantee stability, keep an eye on the vacuum levels.

- Seals and valves: Stop the infiltration of outside air.

- Gas movement is contained and managed by pipelines and chambers.

- Control Systems: Vacuum conditions are maintained by automated systems.

Contemporary Uses of Vacuum Technology

Numerous industries use hoover technology, and we are unaware of how many contemporary conveniences depend on it. The most significant applications are as follows:

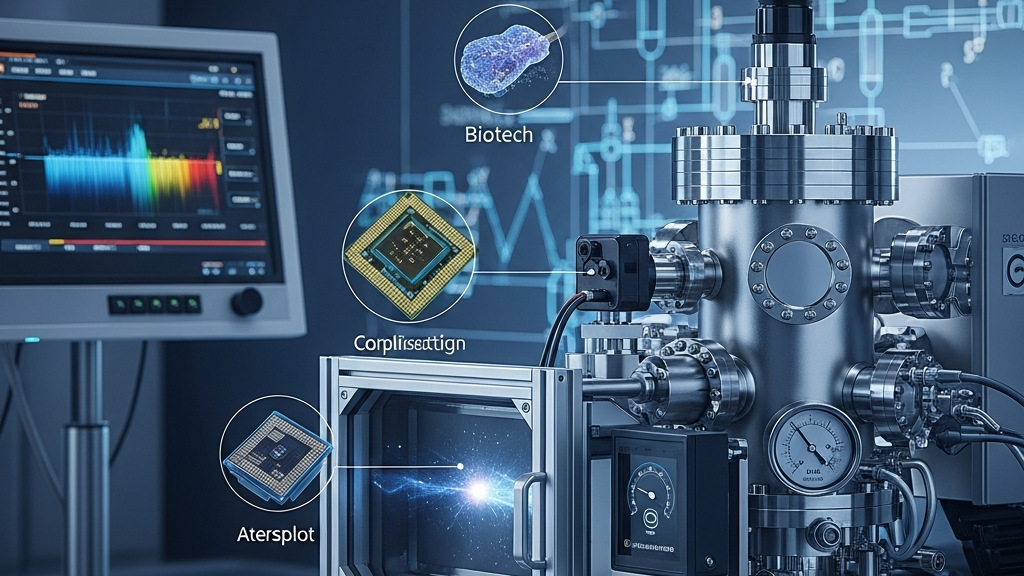

1. Manufacturing of Semiconductors and Electronics

The materials used in modern electronics, such as computers, smartphones, and LED screens, can only be made in vacuum chambers. Using techniques like thin-film deposition and etching, which call for extremely high vacuum conditions to avoid contamination, semiconductor chips are constructed layer by layer. Microchips wouldn’t work reliably without hoover environments.

2. Healthcare and Medical Equipment

Medical research labs and even commonplace medical devices make extensive use of hoover technology. Sterilisation and the manufacturing of surgical instruments and implants are both done in vacuum chambers. For better imaging and precise diagnosis, vacuum systems are also necessary for electron microscopes and magnetic resonance imaging (MRI) equipment.

3. Research on Space and Astronomy

Since space is naturally vacuum, vacuum technology aids in simulating space conditions for research and training. Spacecraft, rockets, and satellites are tested in vacuum chambers that replicate harsh space conditions. Vacuum systems are essential for reducing air-induced interference and distortion in telescopes and other scientific instruments used to study stars and galaxies.

4. The Aerospace and Automotive Sectors

Parts are heated and bonded in vacuum chambers during advanced manufacturing processes like vacuum brazing and vacuum coating to guarantee flawless bonding free from oxidation. This guarantees that parts for cars, spacecraft, and aeroplanes are stronger, lighter, and perform better.

5. The Food and Packaging Sectors

Vacuum technology is used in many food preservation methods. Eliminating air from packaging prolongs shelf life, decreases bacterial growth, and slows down oxidation. Both home kitchens and industrial food production now frequently use vacuum sealing. Another vacuum-based method for preserving delicate foods without sacrificing texture or nutrients is freeze drying.

Vacuum Technology’s Place in Scientific Research

Vacuum technology is essential to scientific research because many experiments need air-molecule-free environments. Controlled vacuum conditions are essential for materials research, particle physics, quantum science, and nanotechnology. Particle accelerators, for instance, need extremely high vacuums to enable particles to travel quickly and interference-free. Significant advancements in space, medicine, and energy have resulted from this.

In conclusion

Despite not being evident in our everyday lives, hoover technology is the foundation of almost all significant technological advancements in the modern era. Vacuum technology enables innovation in everything from the smartphone you hold in your hand to life-saving medical devices to the research that deepens our understanding of the cosmos. Engineers and scientists can create conditions where materials behave differently, reactions occur more cleanly, and products are manufactured with unparalleled precision by adjusting pressure and eliminating air from a space.

Vacuum technology will remain essential in influencing industries, developing science, and raising living standards worldwide as we go forward.